Supplier shortlist

Named manufacturing options aligned to the product category, expected volumes, and intended markets, with clear rationale for inclusion and a summary of how each aligns with the agreed criteria.

Liberty Point runs a structured supplier search and vetting process to identify viable manufacturing partners before production capital is committed. The engagement results in a structured partner evaluation, commercial comparison, and risk analysis designed to support an informed final manufacturing partner selection.

Get in touch

Every engagement starts with a focused scoping call to clarify the product, volumes, markets, and commercial context. This ensures the scope of work and the depth of analysis are agreed upfront, and that the final deliverable reflects the actual decision that needs to be made.

A clear outline of the product category, reference drawings or images, material requirements, and any critical technical specifications.

Expected initial volumes, steady state demand, and any timing considerations that influence supplier suitability.

Intended markets, regulatory considerations, and any geographic or operational constraints that must be respected.

Indicative pricing expectations where known, preferred sourcing regions, existing supplier relationships or exclusions, and any confidentiality sensitivities that must shape how supplier outreach is conducted.

The depth of work varies depending on the product, market, and commercial context. While the process remains structured, certain factors increase the level of screening, engagement, and analysis required before a confident recommendation can be made.

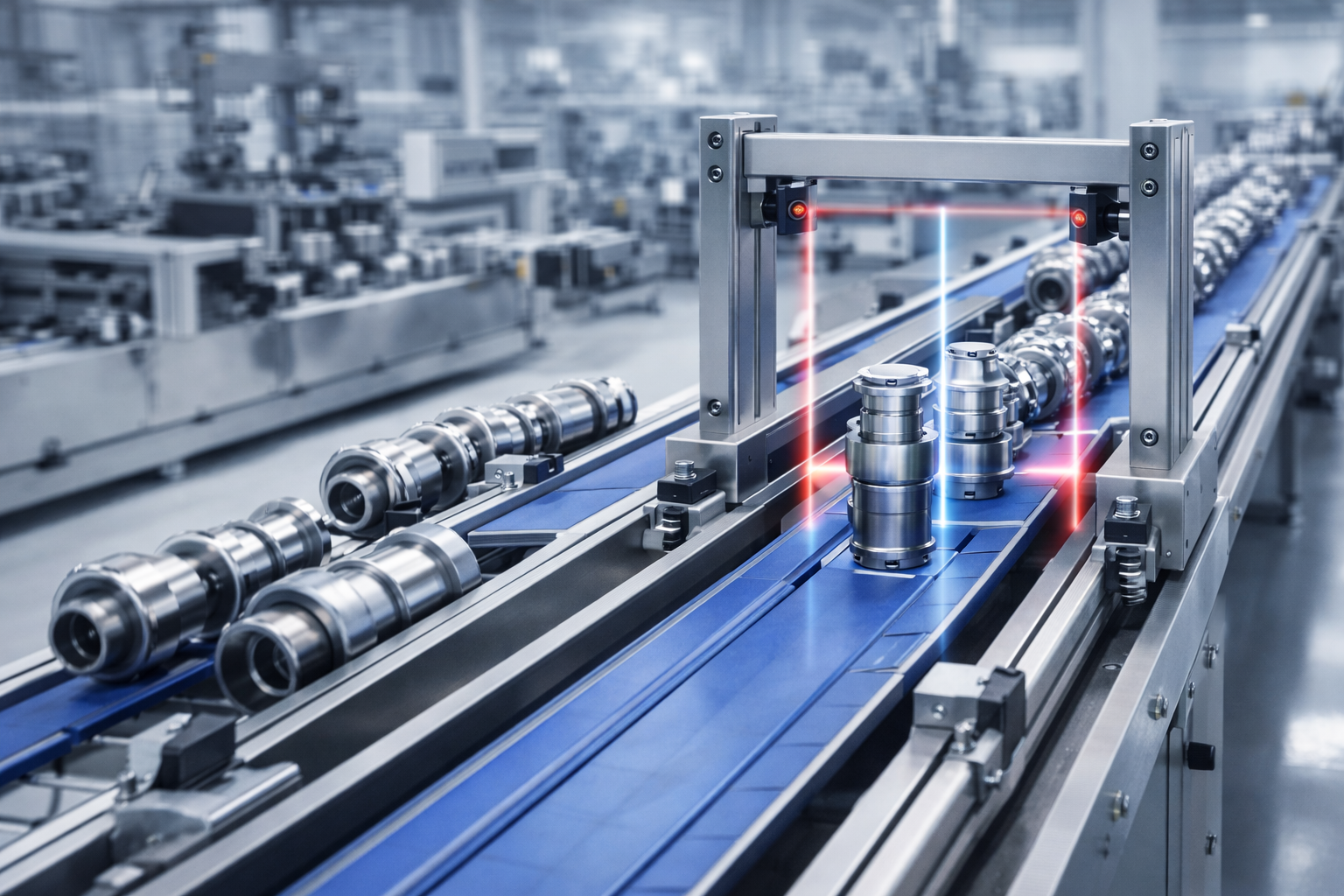

Special processes, certification requirements, tight tolerances, or multi component assemblies increase the depth of technical and operational screening.

Searches that span multiple regions increase outreach activity, comparison effort, and assessment of geographic risk.

In some categories, supplier submissions require additional clarification to test assumptions, validate capability, and surface practical constraints.

Programmes involving tooling investment or uncertain ramp profiles require closer review of feasibility, commercial structure, and long term cost implications.

The output is a structured consolidation of findings gathered through the search and engagement process. It brings together supplier options, commercial parameters, and practical constraints into one coherent view so internal discussions can move forward with clarity rather than assumption.

Named manufacturing options aligned to the product category, expected volumes, and intended markets, with clear rationale for inclusion and a summary of how each aligns with the agreed criteria.

Minimum order quantities, lead times, pricing structures, and headline commercial terms reviewed and normalised so alternatives can be assessed on a consistent and equivalent basis.

Capability limitations, geographic exposure, regulatory considerations, and product specific constraints highlighted to avoid embedding avoidable cost, delay, or compliance risk into the production model.

Practical recommendations on what to validate next, which assumptions require confirmation, and where management focus should be directed before final partner selection.

The engagement is structured as a defined assignment with a clear scope, timeline, and deliverable. This ensures alignment at the outset and avoids scope drift as supplier discussions progress.

A single product manufacturing partner selection assignment is typically structured at USD 4,000.

This covers full market search, supplier screening, direct outreach and discussion, clarification of commercial and operational assumptions, structured comparison of alternatives, and consolidation of findings into a formal decision package.

Scope may adjust where complexity increases, multiple regions are included, or supplier engagement depth extends beyond standard parameters. Multi product programmes, on site validation, or additional execution support are quoted separately.

Typical delivery is three to four weeks from confirmation of agreed requirements.

Before supplier outreach begins, Liberty Point will align on product definition, target volumes, intended markets, technical constraints, confidentiality considerations, and any non negotiable commercial parameters. Clear inputs at the outset protect both pace and quality of outcome.

Where required, Liberty Point can extend beyond partner identification into structured execution support. These extensions are engaged when additional validation, formal documentation, or operational follow through is necessary to secure implementation.

Physical factory visits conducted to verify production capability, operating conditions, quality controls, and management structure before final commitment. Findings are documented clearly to support a go or no go decision.

Preparation of structured RFQ documentation and controlled comparison formats to ensure supplier quotations are complete, aligned, and commercially transparent before selection.

Structured support through initial onboarding, including documentation alignment, production readiness confirmation, and coordination through early implementation milestones.

Defined monitoring of delivery, quality, and commercial performance following selection, with structured issue management where required.

Share your brief and we'll outline how we can support your manufacturing partner search.

Contact us